GoMicro’s Keanan Holder at Flinders University’s Tonsley Innovation District in Adelaide.

THE GoMicro Assessor is being road-tested by growers and entities beyond the farm gate for its ability to determine lentil quality, with a wheat version on track for release in coming weeks, and variants for other grains and pulses expected to be out later this year.

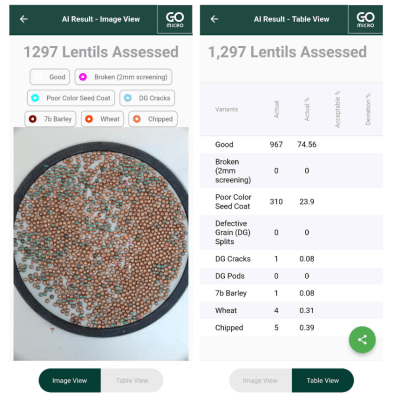

Developed at Flinders University’s Tonsley Innovation District by GoMicro chief executive officer Dr Sivam Krish and his small team, the app assesses samples as photographed with a mobile phone, using artificial intelligence to produce results within minutes.

Its point of difference to other grain AI platforms being developed or used in Australia is its affordability and its handheld nature.

GoMicro is already being used by Queensland company PB Agrifood on soybeans, and GoMicro is in discussions with other companies trading and receiving grain and pulses with an eye to its dual-sided photography system, GoMicro Assessor Plus, being used at the sample stand.

On-farm indicator

At Roseworthy in South Australia, Josh Krieg and family grow wheat, durum, barley and canola as well as pulses.

Mr Krieg said subjectivity surrounding lentil grading has motivated him to trial the GoMicro Assessor, with a bonus being its potential for use in indicating grades of other commodities.

Mr Krieg expects to be using GoMicro from next harvest to assess samples in the header box, and adjust machinery settings to improve chances of getting lentils into the top one or two grades.

“If we see cracks, we could be hitting them too hard, and we might need to slow down the rotors or open up sieves,” Mr Krieg said.

“If there are small lentils coming through, we can add a bit more wind to blow them out.”

A lentil sample and assessment as displayed in the GoMicro app. Photo: GoMicro

Mr Krieg said the biggest reason for downgrading of lentils is poor colour, and he believes GoMicro can provide significant guidance as to how the stand will see his sample.

“The biggest use for us is in lentils, where there is a lot of subjectivity; if we’re going to have issues with anything, it’s lentils.”

“One person sees it one way, another person sees it another; the packer could say this and that is wrong, and you don’t have anything to fall back on.”

“Before we deliver a load, we want to have an idea it’s going to meet standards.”

While the difference between first and second grade is usually around $5 per tonne, the next grade down can see a discount of around $20/t as derived from the cost to the buyer of grading out off types.

“If you knew before you left the farm that that was the grade you were looking at, you wouldn’t take them.”

Mr Krieg the pressure of harvest means growers will often deliver lentils into the No. 3 segregation, even if they expected to get them into the top or second grades.

“The harvest mentality is you want to get them away, so we’ll just tip them off.”

Mr Krieg said if GoMicro indicated a load would go into third grade, the lentils would probably be held on farm to be blended up with higher-grade lentils.

He said adoption of GoMicro by bulk handlers as an indicator of industry standard was the crucial step in making it a worthwhile investment.

“Yes, it’s fantastic, and it’s great, but unless there’s some working together, the full benefit isn’t there.”

He was introduced to GoMicro by Walco director Kurt Walters early this year, and soon after, Mr Krieg bought a GoMicro dome, which now retails for around $330.

The dome allows grain samples to be photographed by a mobile phone camera under ideal conditions for analysis with the app.

Samples can also be assessed with GoMicro on a paper background, but with a slight drop in accuracy.

GoMicro’s AI is developed from many thousands of photographs of samples; it is free at present, but is expected to change to a subscription-based model in the near future.

Agritech group spreads word

Agritech Meetup SA has more than 1000 members, and is a grassroots and informal organisation that brings together growers, developers and other stakeholders.

Through her involvement with Agritech Meetup SA, Yorke Peninsula-based consultant Emma Leonard is helping to spread the word about GoMicro.

“Sivam came over to a meetup we had on YP and talked about technologies, and I thought: ‘This has got a place and I hope we can make it work’,” Dr Leonard said.

“The really big issue is getting both parties trusting the technology.”

While sampling of cereals includes objective and machine-based real-time testing of metrics such as test weight, protein and moisture, grading of pulses relies on the human eye, and results as measured against Grain Trade Australia standards can be rubbery.

“We know that at the receival end, and where we have experienced people, we can have 95pc accuracy.

“When we’re bringing in unskilled labour, it takes time to get those people up to speed, and if anyone is tired and rushed, the accuracy can come down.”

Dr Leonard said GoMicro has the potential to add some rigour to the sampling process for pulses and cereals, and in a more streamlined process.

“This tool offers the option to have more samples.”

In the interest of promoting agtech, Dr Leonard has demonstrated GoMicro to a number of growers in on-farm visits in recent years.

“I took it to a few farmers that were harvesting and they were very enthusiastic.

“They can use it in the paddock to adjust their headers at harvest, and see whether they’re doing harvest damage.

“The bottom line will be when we have objective measurement at the silos used by the handlers too.”

“At the end of the day, we can have a better idea of what quality is; it gives growers a tool to argue their case.”

“It can build a lot of trust.”

GoMicro receivable site-testing R&D manager and CEO Sivam Krish at work at the GoMicro premises at Tonsley in Adelaide.

Receival site testing

Following demonstrations by Dr Krish and GoMicro receivable site-testing R&D manager Keanan Holder, GoMicro is being evaluated by a number of businesses receiving pulses and grains, mostly at South Australian sites.

One of them is AGT Foods Australia at Bowmans north of Adelaide, where a GoMicro dome and the app were trialed on some samples post the 2022-23 harvest.

AGT Foods Australia procurement manager Leigh Wright said the company would not be comfortable using GoMicro to determine grades of receivals yet, but has not ruled out using a more mature iteration of the platform commercially in the future.

“They’ve created the technology, and the more photos and data it has, the better it will get,” Mr Wright said.

Following the wet end to the growing season running into harvest, Mr Wright said weed seeds, wrinkled, cracked and weather-damaged samples have all been seen, so the season just gone has been a tough introductory one for an AI tool like GoMicro.

“I’m certainly impressed by the model, and I’m excited to see where it goes.

“It’s mobile, it’s quick and it’s easy.

“I think they’ve unlocked a process that’s the closest we’ve been to having real-time assessment in a weighbridge sample, but there’s still some work to do.

“That’s part of AI, and how it teaches itself.”

ON MONDAY MAY 15: Read about Cropify, FOSS and Indyn in the final story in our series.

The introductory story in our Grain AI series can be found here.

The second story in the series is about ZoomAgri and can be found here.

Grain Central: Get our free news straight to your inbox – Click here